Digital printing, has come a long way in the last couple of decades. Once a newcomer to the custom apparel industry, it now rivals traditional screen printing in quality and affordability.

What everyone wants to know is: How exactly do the two print methods compare, and which one is better than the other?

The short answer: We use both of these techniques all day every day, and you can count on either one as an excellent and reliable option for customizing apparel.

But like anything, there are pros and cons to each of them. This article will point out the key differences to be aware of and help you understand what’s best for your particular needs.

First, let’s define the two print methods, then get into the details of the comparison.

What is screen printing?

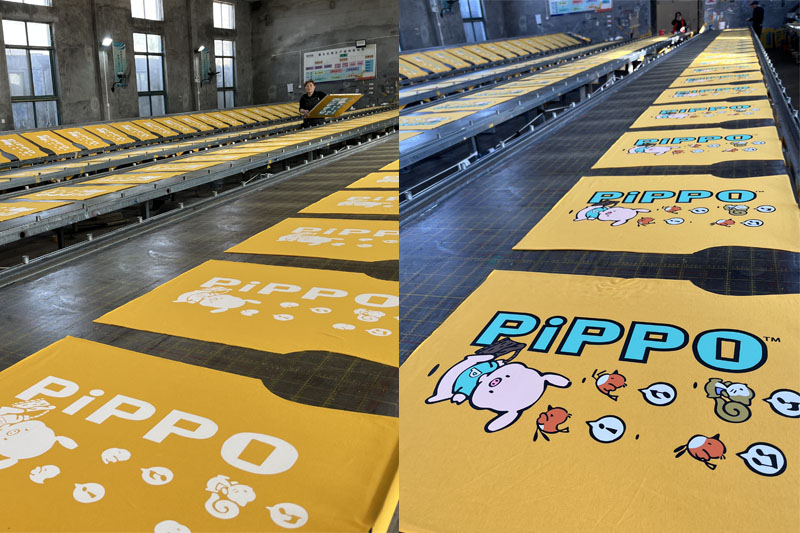

Screen printing (aka silkscreen) is the most widely known and widely used form of decorating apparel, a traditional technique dating back thousands of years. Each color of ink is pushed through a different stencil (screen) and layered onto the surface of the textile (fabric), then cured (heated) to set the ink.

In what ways is screen printing better than Digital printing?

Screen printing is better for:

Larger, high-volume orders.

Unique or oversized print areas.

Single-color prints, such as text or logos.

Specialty or special FX inks.

Printing on polyester and other synthetic fabrics.

Vibrant colors on dark-colored fabrics.

When exact color matching is required.

What is Digital printing?

Digital printing is the process of printing digital-based images directly onto a variety of media substrates. There is no need for a printing plate, unlike with offset printing.

Digital printing maps out an image onto a chosen surface – a shirt, a mug, a hat, a bag, etc. – and using minute droplets of ink transfers that image onto it. Its simplicity and minimal use of equipment make digital printing one of the most cost-effective printing forms out there. It is also ideal for small batches of products, making it one of the best Print on Demand services options.

In what ways is Digital printing better than screen printing?

Direct-to-garment is better for:

Smaller, simple orders (including single pieces).

Standard print locations and print sizing.

Printing on 100% cotton.

Designs with lots of detail.

Gradients and other photographic elements.

Designs with many colors and blends.

When soft feel or lightweight print is important.

Screen printing vs. Digital printing: What’s the difference?

Screen printing is the classic technique of pushing plastic-based ink through the mesh and onto the garment. It’s the most versatile and popular printing method. Digital printing is the newer technique of spraying ink onto the garment. It’s the fastest and easiest way to print, especially designs with many colors.

To fully answer the question, let’s break down these top ten factors to explain exactly how the two print methods compare.

Digital printing vs. Screen Printing: Vibrancy

Vibrancy is the combination of color saturation and brightness. While DTG printing has made impressive advancements in recent years, it still has a slightly duller appearance when compared to screen printing.

When you want your design to pop off the shirt, screen printing is the method that stands out.

So what accounts for the difference?

Screen printing ink

Traditional screen printing uses Plastisol ink, which is composed of PVC particles suspended in a plasticizing emulsion (there are eco-friendly, non-PVC Plastisol inks on the market). This type of ink is extremely opaque, which can create a bright white underbase on dark garments, something that is key for vibrancy.

On top of that (literally) Plastisol inks come in the most vibrant colors available, such as fluorescents. The top ink brands offer a standard set of base colors to be used for mixing into the thousands of custom Pantone colors.

Which one to use?

The end result will depend on the type of fabric being used, so it’s important to choose a fabric that is suitable for your desired printing method. Digital printing is a great option for baby clothing because it offers an array of colors and designs.

Furthermore, digital printing eliminates the need to buy multiple screens or use special inks that might not be safe for babies.

Ultimately, choosing between digital printing and screen printing for baby clothing will depend on the desired look, cost, and sizing needs.

With these considerations in mind, you can make an informed decision about which printing method is best for your project. In conclusion, digital printing is the better choice when it comes to baby clothing.

It’s a more cost effective option with a wider range of colors and designs, and is much safer for babies since there are no special inks or screens used.

Furthermore, the prints produced by digital printing last longer and won’t fade or crack over time. Ultimately, digital printing is the ideal solution for creating high-quality prints on baby clothing.