Introduction

In the realm of baby clothing manufacturing, ensuring the utmost safety and durability of products is paramount. This article explores the rigorous quality control processes that manufacturers employ to meet these essential criteria.

Regulatory Standards and Compliance

Compliance with international safety standards

Manufacturers must adhere to stringent international safety standards to guarantee that baby clothing is safe for its intended use.

Overview of relevant regulations (e.g., CPSIA, EN standards)

Regulations such as the Consumer Product Safety Improvement Act (CPSIA) in the US and European EN standards outline specific safety requirements for baby textiles.

Importance of meeting regulatory requirements

Meeting these requirements not only ensures legal compliance but also builds trust with consumers and retailers alike.

Fabric and Material Selection

Choosing safe and durable fabrics

Fabric selection is critical, focusing on materials that are hypoallergenic, non-toxic, and free from harmful chemicals.

Testing fabric quality (e.g., thread count, chemical testing)

Fabric undergoes rigorous testing for durability, comfort, and safety, including tests for thread strength and chemical residues.

Impact of fabric choice on baby comfort and safety

The choice of fabric significantly impacts the comfort and safety of baby clothing, influencing factors like breathability and skin sensitivity.

Production Process

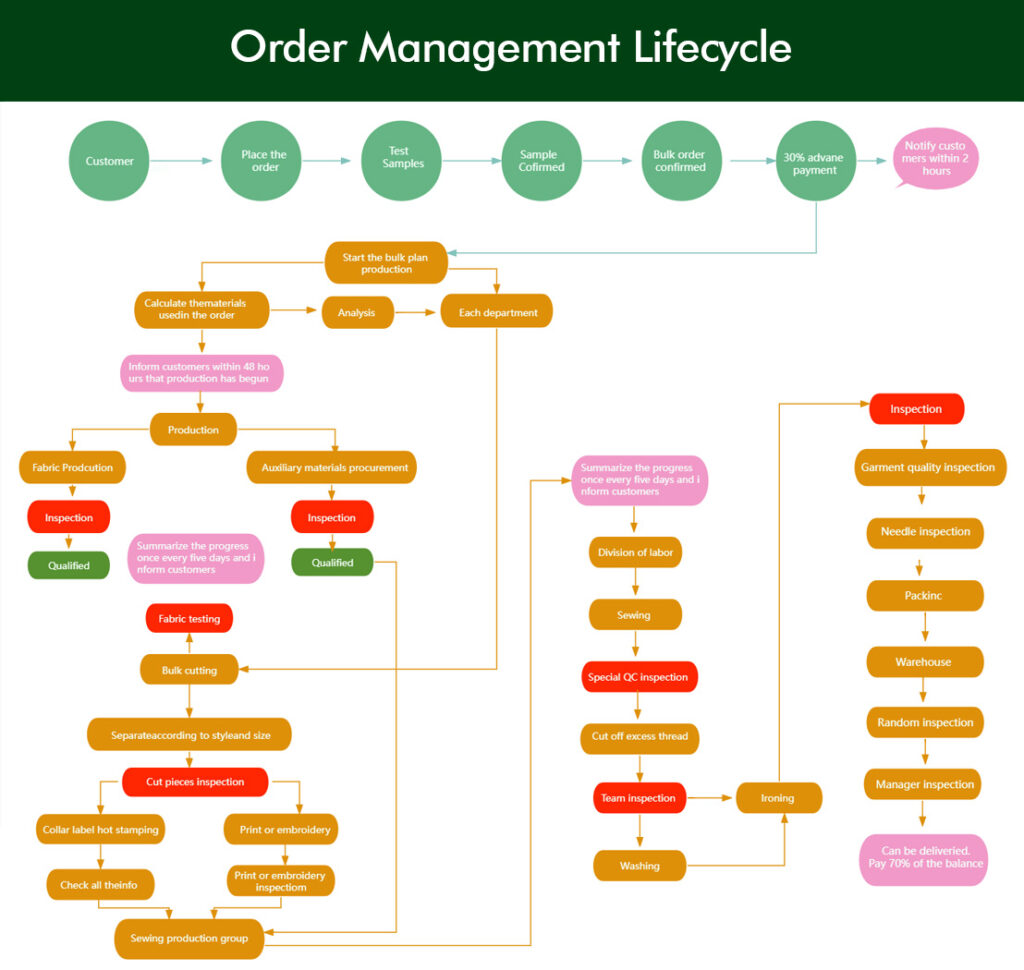

Steps in the manufacturing process

From design to final production, every step is carefully monitored to maintain quality standards.

Quality checkpoints during production (e.g., cutting, sewing, finishing)

Critical checkpoints ensure that each garment meets specified criteria for stitching, fit, and overall construction quality.

Role of automated systems in quality assurance

Automation plays a key role in maintaining consistency and precision throughout the manufacturing process.

Testing and Inspection Protocols

Types of quality tests conducted (e.g., tear resistance, colorfastness)

Various tests, including tear resistance and colorfastness, are conducted to ensure durability and aesthetic longevity.

Importance of third-party testing and certification

Independent testing by accredited laboratories provides unbiased validation of product safety and quality.

In-house vs outsourced testing facilities

Manufacturers choose between in-house testing capabilities or outsourcing to specialized facilities based on cost-effectiveness and expertise.

Packaging and Labeling Standards

Ensuring accurate labeling (e.g., size, care instructions)

Clear and accurate labeling helps consumers make informed choices and ensures proper care of the garment.

Packaging considerations for safety and hygiene

Hygienic packaging protects products from contamination and ensures they reach consumers in pristine condition.

Environmental impact of packaging choices

Sustainable packaging options reduce environmental footprint, aligning with consumer preferences for eco-friendly products.

Storage and Transportation

Warehouse conditions for maintaining product integrity

Optimal storage conditions, including temperature and humidity control, prevent damage and deterioration.

Shipping considerations to prevent damage

Careful shipping practices minimize the risk of product damage during transit, preserving product quality.

Temperature and humidity control during storage

Maintaining controlled environments during storage preserves garment integrity and ensures long-lasting quality.

Customer Feedback and Improvement

Importance of post-production feedback

Feedback from consumers and retailers helps manufacturers identify areas for improvement and innovation.

Continuous improvement strategies

Implementing feedback-driven improvements enhances product quality and customer satisfaction over time.

Case studies of successful quality control implementations

Examples illustrate how robust quality control measures lead to enhanced brand reputation and consumer trust.

Conclusion

In conclusion, quality control in baby clothing manufacturing is indispensable for ensuring the safety, durability, and overall quality of products. By adhering to rigorous standards, manufacturers not only meet regulatory requirements but also foster trust and loyalty among consumers and retailers.

FAQs

How are baby clothes tested for safety?

Baby clothes undergo rigorous testing for factors like choking hazards, chemical safety, and durability.

What should retailers look for in quality baby clothing?

Retailers should prioritize safety certifications, durable materials, and clear labeling in quality baby clothing.

Why is durability important in baby clothing?

Durability ensures that baby clothes withstand frequent washing and maintain their quality over time.

How can manufacturers ensure product safety across different markets?

By complying with international safety standards and adapting products to meet local regulations.

What role do regulations play in ensuring quality baby clothing?

Regulations set minimum safety and quality standards, ensuring consistency and consumer protection.